Main photo provided by Canva. All other photos in this article are provided by the designer.

There you are, happily sewing away, when—snap!—your thread breaks. Again. Cue the sigh, the re-threading, and perhaps a few muttered words under your breath. Sound familiar?

Thread breaks can be such a common hiccup in sewing and happen to both beginners and experienced stitchers. But here’s the good news: most of the time, there’s a simple reason behind it—and an easy fix, too. In this article, we’ll look at causes from the basics, like tension and needles, to more advanced culprits you might not have considered. Whether you’re new to sewing or just fed up with stopping mid-stitch, we’ve got you covered.

Quick Fixes for Common Issues – Check First!

Before diving into machine settings or calling a technician, try these simple solutions. They solve most thread-break problems in seconds.

TIP! Keep your sewing machine manual nearby; consider it your new best friend!

- Use Quality Thread. Cheap thread can have an uneven texture or hidden weak spots that lead to breakage. Choose trusted brands and opt for cotton-poly blends for better durability. Quick test: Unravel a short length from the spool and pull it—quality thread will feel stronger and more resistant to snapping.

- Check Your Needle. A dull, bent, or incorrect needle can cause the thread to shred or snap. Use the correct needle for your fabric and thread weight and replace it regularly—at the start of a new project or after 6-8 hours of use, or if you notice skipped stitches or fraying.

- Proper Threading. Even experienced sewists can sometimes mis-thread a machine. Unthread both the top thread and the bobbin, then rethread carefully, making sure the thread passes through all guides and tension discs. Your manual or a short video can be a big help here.

- Thread Cap Matters. If your spool sits horizontally, a mismatched thread cap can cause snagging. Choose the correct cap or a vertical spool position to ensure the thread feeds smoothly.

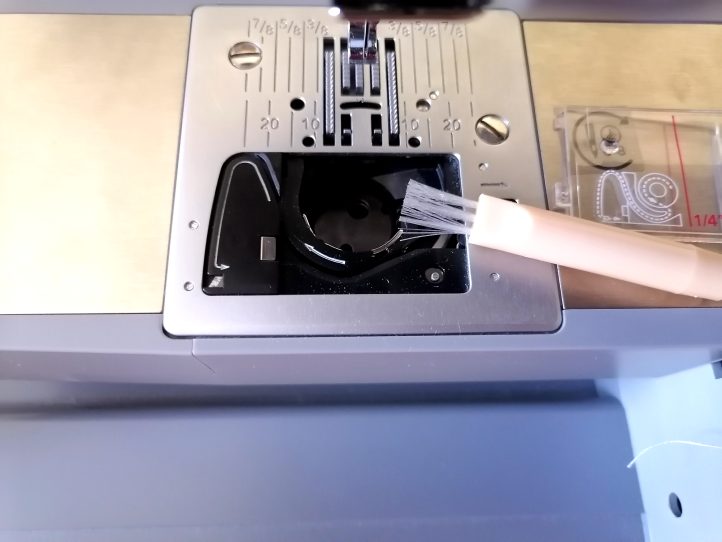

- Clean Your Machine. Lint, dust, or leftover thread bits can affect tension and thread flow. Regularly brush out the bobbin case and beneath the needle plate. Your manual should show you how to do this correctly.

Next-Level Fixes

If the basics don’t solve the issue, these next-level tweaks can help fine-tune your stitching setup.

- Adjust Tension Settings. Too much tension on the upper thread can cause it to snap. Try loosening it slightly and test on some scrap fabric. Check your manual for the tension settings and how to adjust them.

- Check Bobbin Quality and Placement. Choose a bobbin that matches your machine’s brand and ensure it is wound evenly and inserted properly.

- Inspect the Thread Path. Run your fingers (gently) along the thread path to feel for any burrs, snags, or misaligned guides that may be catching the thread.

- Slow Down. High-speed stitching increases friction—especially with delicate or specialty threads. Reducing your stitching speed can ease tension on the thread.

Advanced Tips – Precision and Performance

For those tackling complex or high-stakes projects, these advanced strategies can make a big difference.

- Match Thread Type to Project. For delicate fabrics, opt for a fine thread. For heavier materials, such as denim, choose a thicker, more durable thread. Always test it out on a piece of scrap fabric first.

- Use a Thread Stand or Cone Adapter. Large spools or cones don’t always feed correctly on domestic machines. A thread stand can ensure the feed is smooth and consistent.

- Upgrade Your Needle. Specialty threads usually work best with the right needles. Give topstitch, Microtex, or metallic needles a try- they help prevent shredding and snapping.

- Know When to Call a Technician. If your machine keeps breaking threads despite your efforts to fix the issue, the problem might be internal. Signs such as constant thread snapping, looping, or unusual noises may suggest timing or tension issues that require a professional inspection.

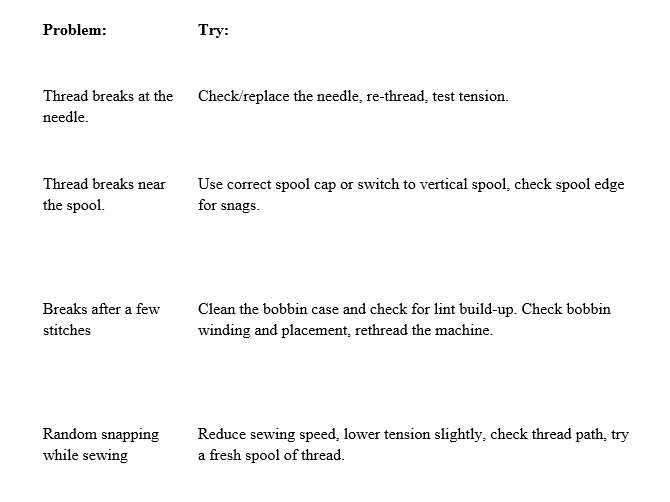

Bonus: Troubleshooting Cheat Sheet

Need a quick reference? Keep this cheat sheet near your sewing station:

Thread breaks can really throw off your sewing groove—but they don’t have to. Once you know what to look out for, preventing them becomes a whole lot easier. A quick check of your tension, needle, thread, or even how you’re threading the machine can save you a lot of hassle.

So the next time your thread snaps, don’t panic—pause, troubleshoot, and carry on. With these tips in your sewing toolbox, you’ll spend more time creating and less time fixing!